Lunar eye use cases

01

Equipment Maintenance Management System

With Lunar Eye you can improve the efficiency of equipment maintenance and staff management.

Platform Users can:

- Monitor equipment in real time using video cameras, IoT devices, and GPS trackers

- Recognize individual pieces of equipment using visual markers

- Create detailed reports on equipment (users, time of use, and condition)

- Plan maintenance activities and generate automated commands for IoT equipment

- Create and assign maintenance tasks

- Track employee availability, actions, movements, and behavior in real time

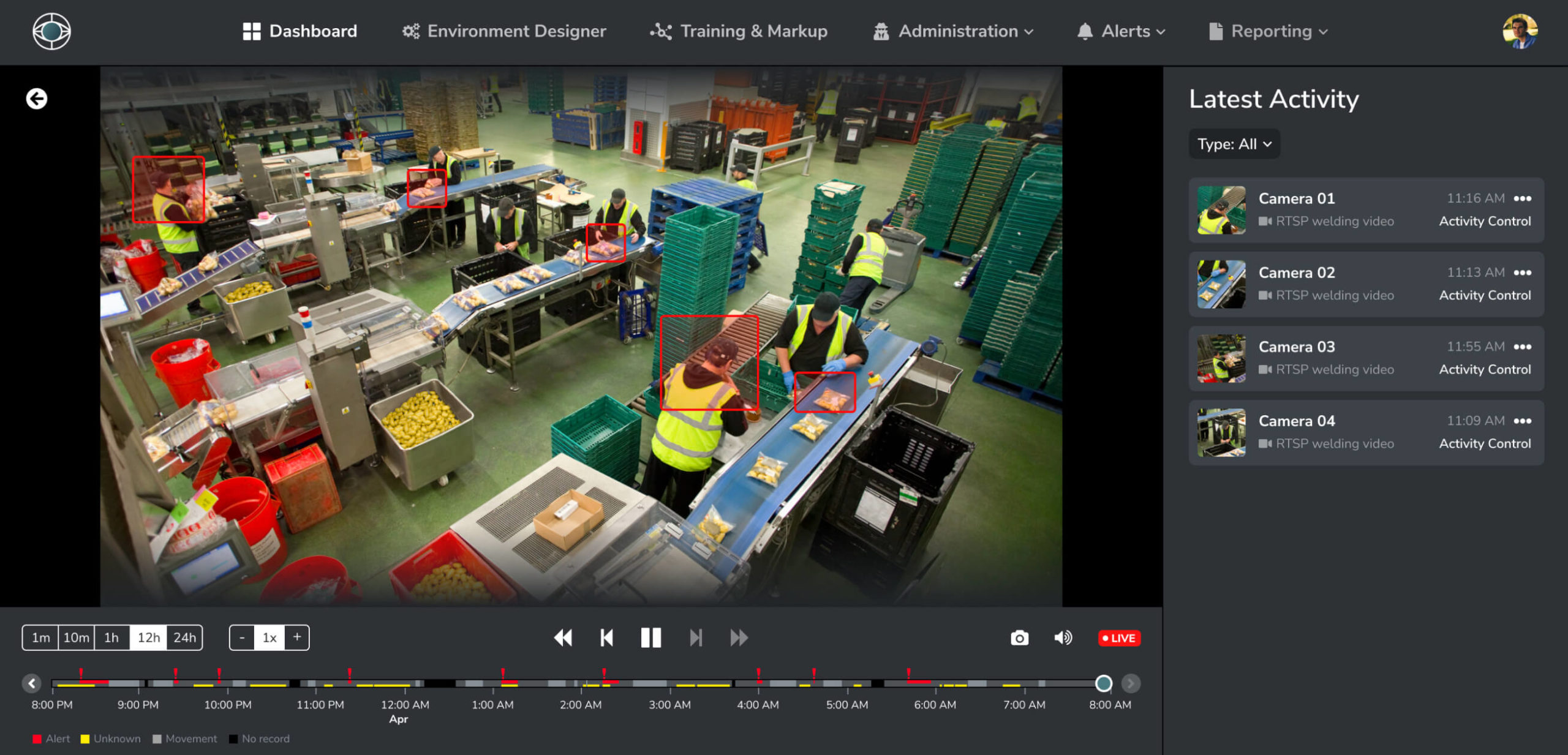

02

Real-Time Manufacturing and Maintenance Control

Lunar Eye enables AI-driven manufacturing processes automation and proactive machine maintenance control.

Platform users can:

- Monitor and control various moving parts of assembly lines and areas in real time

- Automate production lines, predict failures, and prevent congestion

- Identify and track individual fragments or parts of a specified machine from the video stream in real time while simultaneously storing the collected data for later analysis and or action.

- Track, count, and measure objects on assembly lines

- Monitor high risk zones, employee actions, and movements in order to improve workplace safety

- Automatically retrieve data from screens, displays, and timers

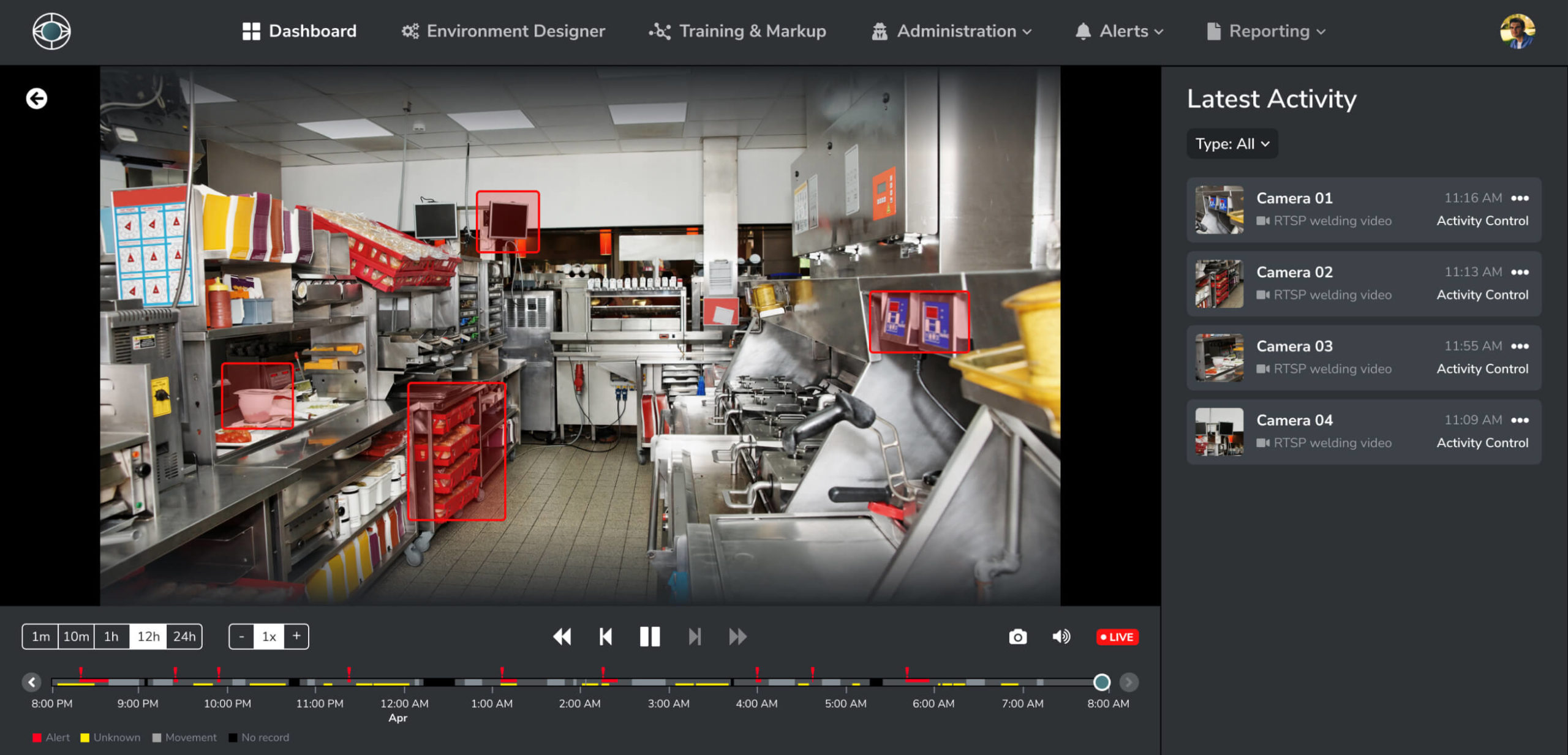

03

Real-Time Object Detection and Quality Assurance

With Lunar Eye you can optimize production and automate quality control.

Features:

- Structural quality – Check for the presence or absence of components or parts and check for the presence or absence of foreign elements on or in an object.

- Object parameter measurement – Calculate the volume and weight of homogeneous objects

- Dimensional quality – Measure object dimensions and compare dimensional accuracy within geometric tolerances.

- Color monitoring – Measure and monitor the intensity and spectrum of object illumination

- Product labeling and packaging control – identify incorrect labels, ensure proper label placement and alignment, monitor the product packaging process,

- Sustainable production – Calculate the number of products produced and compare it to the number of materials used in real time. Predict the amount of raw materials needed by comparing the number of products produced

- Waste control – Identify products on the shelves and notify users of their expiration dates.

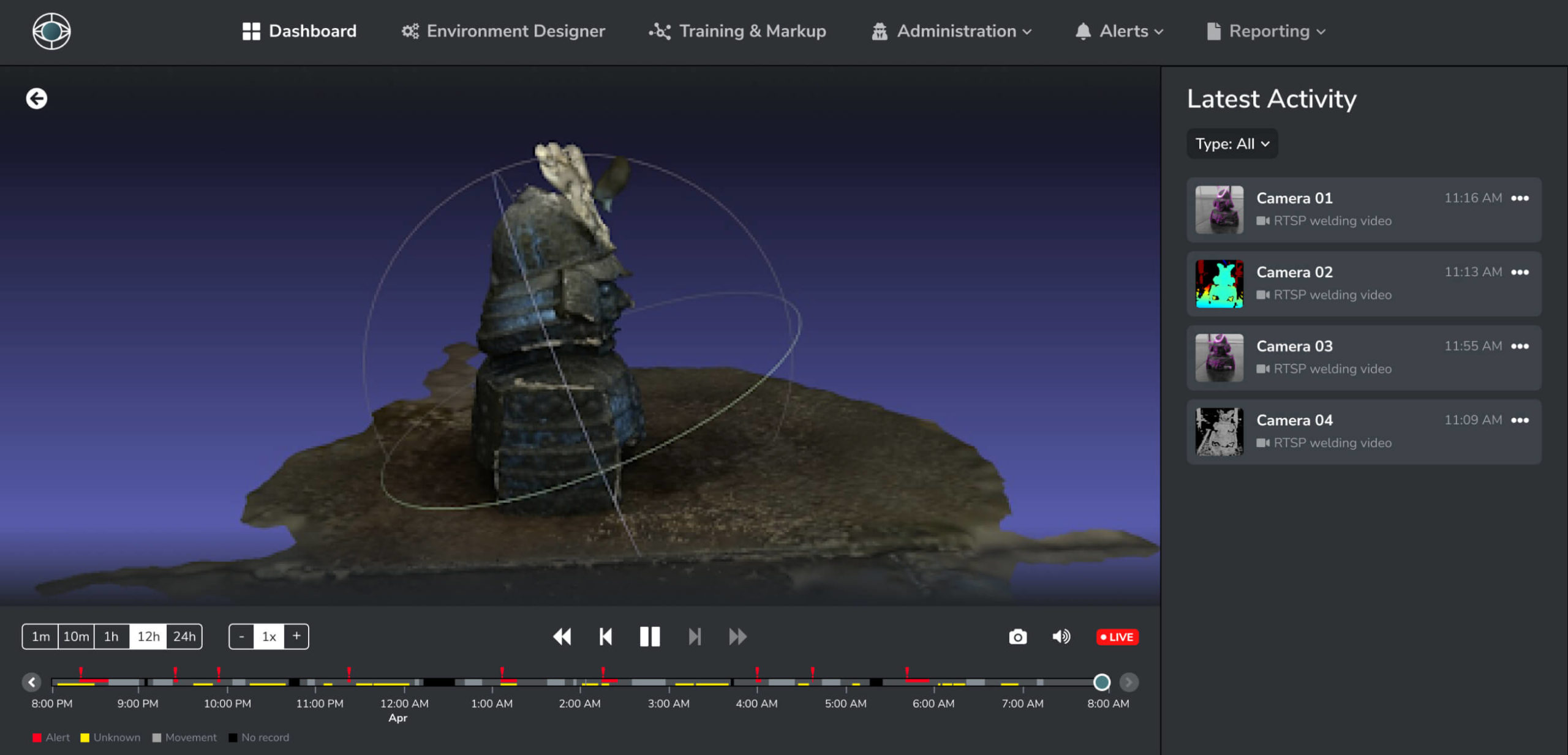

04

Multi-View 3D Reconstruction

We use photogrammetry and structure from motion approach to build a 3D model from 2D images. The system takes video or a sequence of frames of one object as an input data for building a 3D model.

Lunar Eye platform will perform the following:

- Key points detection and descriptors construction

- Nearest neighbor matching key points matching

- Constraint filtering

- Robust model estimation

- Incremental Structure from Motion (SfM)

- Dense point-cloud reconstruction

- Mesh reconstruction

- Mesh refinement

- Mesh texturing

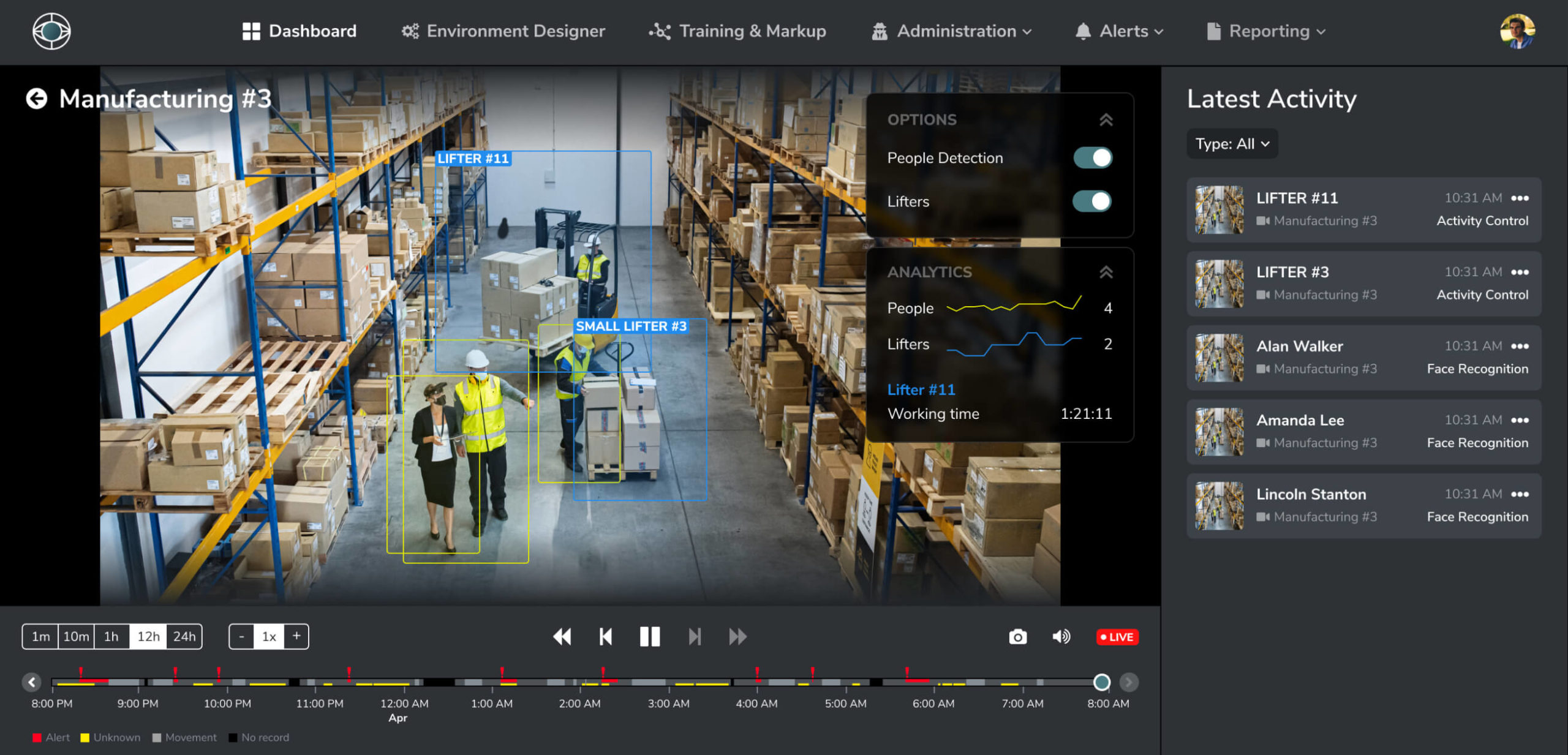

05

Real-Time Safety and Security Control

Lunar Eye platform offers smart AI monitoring to help businesses improve the physical security of their facilities.

Features:

- Face recognition and identification

- Multithreaded search across multiple video sources and cameras

- Real time recognition and detection of objects, people movement, gestures, and behavior

- Monitoring of specified areas and alerts: Will detect trespassing, size of crowds, loitering, and unattended objects

- Ability to search for a specific person while recreating a chronological map on their movement

06

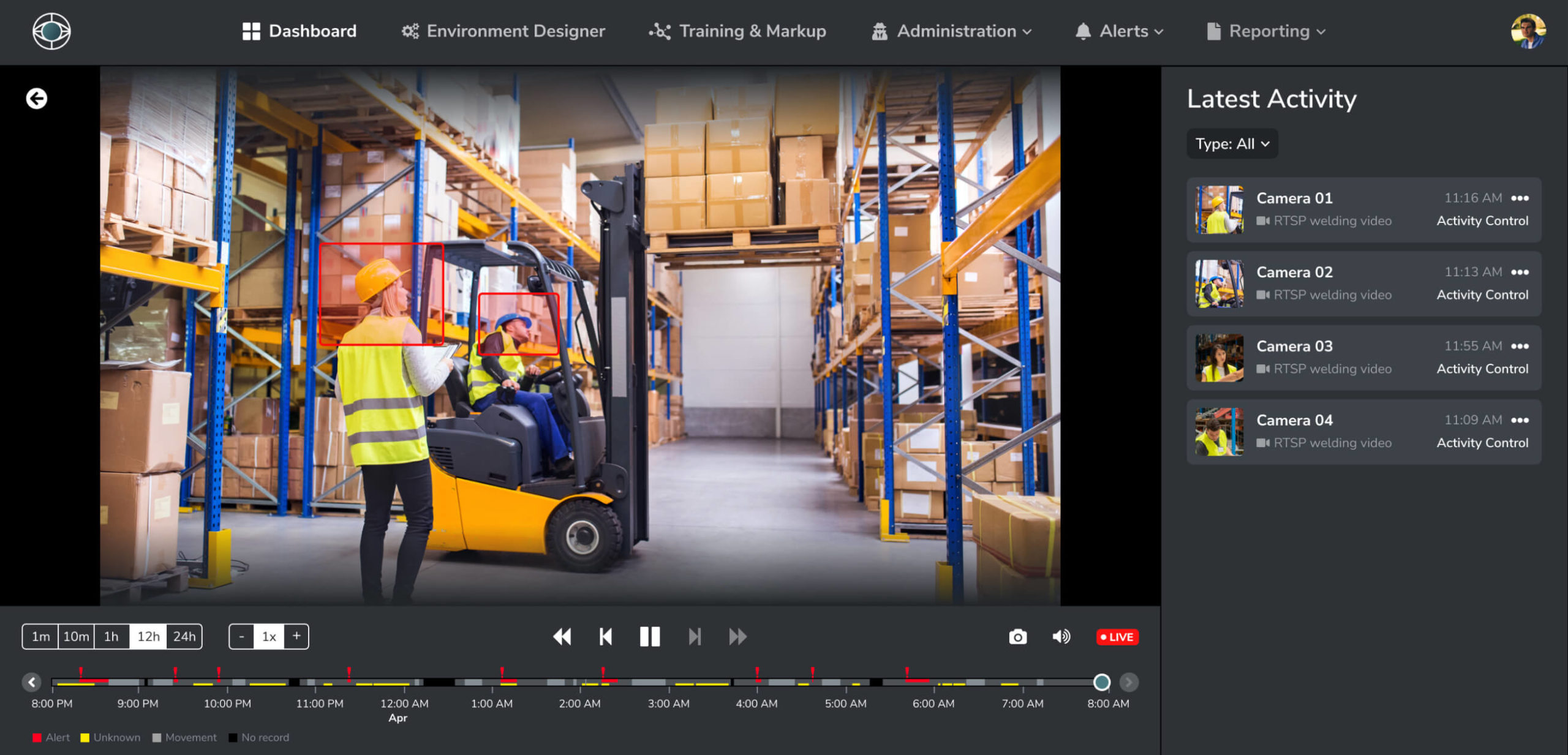

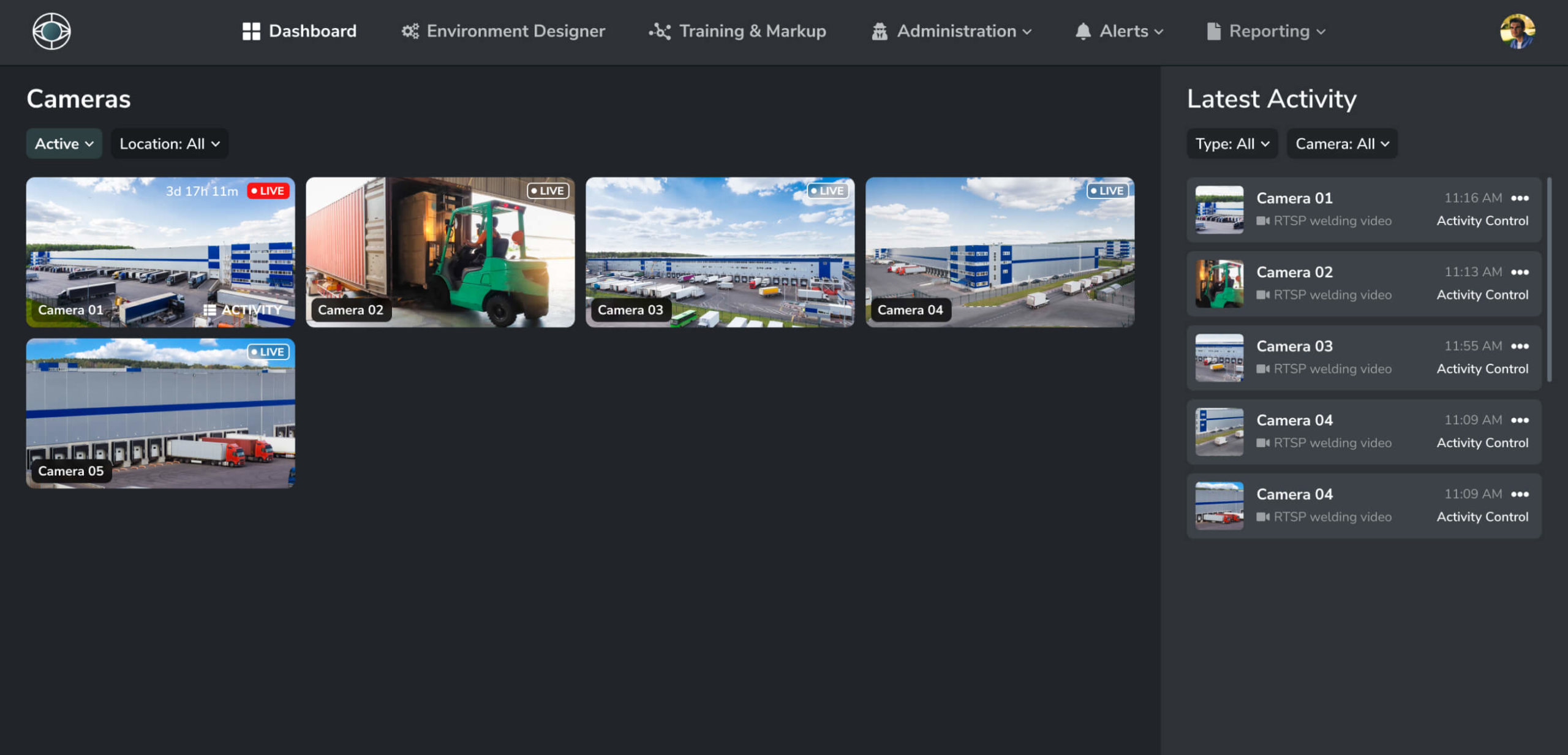

Real-Time External and Internal Logistics Management

Lunar Eye puts users in the driver’s seat of daily logistics operations by offering AI‑powered automation.

External areas:

- Vehicle monitoring. Autonomous vehicle tracking and automated alerts on departures and arrivals.

- Cargo monitoring and control. Autonomous cargo monitoring with real- time alerts based on loading and unloading while providing real time alerts on safety, security, and method of shipment.

Internal areas:

- Warehouse logistics. The system analyzes work processes and creates detailed statistics on workforce actions such as: employee movements, gestures, chronology of movements, compliance with product manufacturing, packaging and storage.

- Product monitoring. Tracks movement of goods and services across the entire plant while identifying shortcomings in work processes. Will simultaneously provide details on product quality (color, shape, size and texture) and notifies users of Predictive modeling. The Lunar Eye system helps reduce injuries in the workplace by tracking workforce movement by individual body parts while autonomously alerting Lunar Eye users on potential injuries or accidents that are occurring or will occur.

Want to discuss how to implement Lunar Eye within your organization?

Want to discuss how to implement Lunar Eye within your organization?

For more information, please contact: Lunar Eye +1 800 761-6990

Lunar Eye Corporation :